| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : NC8363

Model Number : 8363

Certification : ISO9001,CE,SGS

Place of Origin : Mainland China

MOQ : 100 pcs

Price : Can talk

Payment Terms : T/T, L/C

Supply Ability : 60,000 pcs monthly

Delivery Time : 30 days

Packaging Details : Wooden Case

Part Name : Engine Block

Material : Cast Iron

Process : Sand Casting

Application : Industry

Surface Treatment : Sandblasted+primer coating

Size : Customized

Cast Iron Engine Block Resin Green Sand Casting

Product Details

Production Process

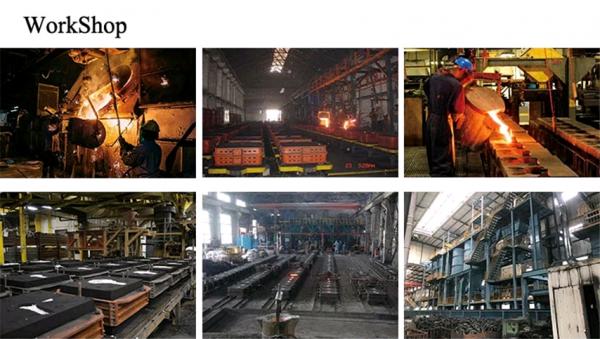

About Us

Our main products are GG15 ~ GG30 gray iron castings and GGG40 ~ GGG70 ductile iron castings We can do the machining,we have the horizontal machining center, 5 vertical machining centers, 6183 type CNC lathe, 6166 type CNC lathe, 6163 type CNC lathes, 6152 type CNC lathes, 6140 type CNC lathes, 6136 type CNC lathes, 6132 type CNC lathes, CNC milling machines, broaching machine and other main machining equipments.

For the convenience of customers, our factory can custom all kinds of mould for clients to provide one-stop services from drawings to deliver castings, we uphold the 'customer focus and exceed customer expectations "business philosophy, in good faith with the pragmatic, wholeheartedly welcome the global merchants to patronize, complicity development, create brilliant.

Quality Control

FAQ

1. How to prevent the formation of air holes in castings?

The effective methods to prevent bubbles are: reducing the gas content in the metal liquid, increasing the air permeability of sand mold, and adding an air riser at the top of the mold cavity.

|

|

Cast Iron Engine Block Resin Green Sand Casting Images |